SIMTI - Materials Science and Engineering for Innovative Technologies

Mission

SIMTI pursues the common calling of its members to combine fundamental research with technological and pre-industrial development of innovative materials. The aim is to build a multifaceted cultural identity, which can apply to all class of materials and their combinations in order to define a sound, integrated and highly competitive approach to meet the demanding and complex requirements of new materials and innovative fabrication technologies. Scientific collaboration with international partners and companies, leaders in the material and device fabrication, is SIMTI priority. In particular, the focus is on new knowledge and technology development to be combined, complemented and supported by the acquisition of structural funds from European and International bodies. The scientific reputation of SIMTI and the significant presence of its members in leading bodies and boards are key to support the natural vocation of SIMTI members towards innovative research and technology development.

Main Targets

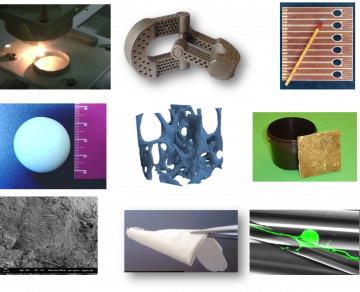

- Study of processes and innovative technologies for the production, consolidation and eventual thermal treatments of alloys for high temperature applications and chemically aggressive environments, of tools for cold and hot forming, of light alloys, of iron-based alloys with advanced properties and of precious metals; the study of innovative techniques and materials is combined with evaluation of process sustainability so to extend their industrial application, also in agreement with the main leaders of each reference sector at national and international levels

- Optimization of Additive Manufacturing for the production of components and microstructures impossible to be obtained with other manufacturing processes and evaluation of the characteristics of the products as a function of processing parameters

- Development of ceramics and micro and nanostructured composites for extreme environments (turbines for energy and propelling applications at high temperature T>1300°C).

- Development and recycling of nanocomposites for structural and functional applications in the field of transport

- Development of innovative ceramic compositions and treatments to fabricate new devices for sensors, mechanical, thermal, environmental and biomedical applications

- Design and manufacturing by 3D printing (in particular with Robocasting and Digital Light Processing techniques) of engineering ceramics for the above-mentioned applications, and in particular for biomedical scaffolds and environmental devices (e.g. CO2 capture)

- Tailoring of powders and ceramics at the nano-micro and macro structural level.

- Development of innovative cements, with particular attention to sustainability. Development of mortar and concrete containing SCM or waste products. Development of self-healing cementitious materials.

- Design and development of innovative materials, specifically referring to bioplastics and reactive-extrusion processes in order to provide peculiar functionalities suitable for enhancing their flame retardancy and thermo-mechanical features as well.

- Surface engineering devoted to: i) design and obtainment of multifunctional coatings having enhanced thermal, antibacterial and fire behavior; ii) utilization of microorganisms suitable for degrading elastomeric systems (even vulcanized)

- Development of new metallic materials and components through additive manufacturing technologies

- Increase the penetration of additive manufacturing in the industrial environment through the development of next generation machines.

- Design and development of multifunctional, smart nanostructured materials

- Development of sustainable processes to produce multifunctional 3D structures using 3D printing and electrospinning technologies for applications in the tissue regeneration, energy and environmental sectors (objective with close synergies between the ceramic, additive manufacturing and biomaterials sections)

- Engineering of injectable formulations (cements, hydrogels) for the release of therapeutic and/or bioactive agents (objective with close synergies between the ceramic and biomaterials sections)

- Innovative and green materials for the construction sector: binders with low environmental impact, structural materials derived from industrial by-products, self-healing and self-sensing construction materials, materials for the capture and permanent storage of CO2

Leader

Research teams

-

Additive Manufacturing

Leader: FINO PAOLO

Permanent staff: ACTIS GRANDE MARCO , AVERSA ALBERTA , BADINI CLAUDIO FRANCESCO , BASSINI EMILIO , BIAMINO SARA , BONDIOLI FEDERICA , COPPOLA BARTOLOMEO , LOMBARDI MARIANGELA , LUPONE FEDERICO , MANFREDI DIEGO GIOVANNI , MARCHESE GIULIO , MESSORI MASSIMO , MONTANARO LAURA , OSTROVSKAYA OXANA , PADOVANO ELISA , PALMERO PAOLA , PAVESE MATTEO , TULLIANI JEAN MARC CHRISTIAN , UGUES DANIELE , VITALE BROVARONE CHIARAResearchers (RTDA): BHATT BHASKARANAND , COLUCCI GIOVANNA , FIUME ELISA , GOBBER FEDERICO SIMONE , NOE' CAMILLA , THANGAMANI GEETHAPRIYAN

PhD, Post-docs and Grant researchers:

ARCIERI NICOLO' , BOSIA SILVIA , DI STURCO SAMUELE , FELICIONI STEFANO , FONTANA LUCA , LAGALANTE ILARIA , LERDA SERENA , MARTUCCI ALESSANDRA , PIATTI ELISA , REZAEI SINA , SACCHI FRANCESCA , TALUR CHANDRASHEKAR GNANESH , TROVATO MIRKO , VANZETTI MATTEO , YADEGARI MOHAMMAD JAVAD

ARCIERI NICOLO' , BOSIA SILVIA , DI STURCO SAMUELE , FELICIONI STEFANO , FONTANA LUCA , LAGALANTE ILARIA , LERDA SERENA , MARTUCCI ALESSANDRA , PIATTI ELISA , REZAEI SINA , SACCHI FRANCESCA , TALUR CHANDRASHEKAR GNANESH , TROVATO MIRKO , VANZETTI MATTEO , YADEGARI MOHAMMAD JAVAD

-

ALL-Polymer

Leader: MALUCELLI GIULIO

Permanent staff: ARRIGO ROSSELLA , BATTEGAZZORE DANIELE , FRACHE ALBERTO , IACONO GIUSEPPINAPhD, Post-docs and Grant researchers:

BERNAGOZZI GIULIA , CRAVERO FULVIA , GNOFFO CHIARA , LORENZI ELEONORA , QUERO ALESSANDRA

BERNAGOZZI GIULIA , CRAVERO FULVIA , GNOFFO CHIARA , LORENZI ELEONORA , QUERO ALESSANDRA

-

Biomaterials

Leader: VITALE BROVARONE CHIARA

Permanent staff: COPPOLA BARTOLOMEO , FINO PAOLO , FIORILLI SONIA LUCIA , LOMBARDI MARIANGELA , MONTANARO LAURA , PALMERO PAOLA , TULLIANI JEAN MARC CHRISTIANResearchers (RTDA): FIUME ELISA

PhD, Post-docs and Grant researchers:

BARBERI JACOPO , BENEDETTO MAS ALICE , COVIELLO LAURA

BARBERI JACOPO , BENEDETTO MAS ALICE , COVIELLO LAURA

-

Ceramic Materials

Leader: PALMERO PAOLA

Permanent staff: BADINI CLAUDIO FRANCESCO , BIAMINO SARA , COPPOLA BARTOLOMEO , FINO PAOLO , FIORILLI SONIA LUCIA , LOMBARDI MARIANGELA , MONTANARO LAURA , PAVESE MATTEO , TULLIANI JEAN MARC CHRISTIAN , VITALE BROVARONE CHIARAResearchers (RTDA): FIUME ELISA

PhD, Post-docs and Grant researchers:

ABBAS ZAHID , BERTERO ARIANNA , BONFANTE FRANCESCA , BUDAEVA ANASTASIIA , FERRARA GIUSEPPE , GULLO FRANCESCA , LI BING , MILOVANOV YURII , RIQUET GUILLAUME

ABBAS ZAHID , BERTERO ARIANNA , BONFANTE FRANCESCA , BUDAEVA ANASTASIIA , FERRARA GIUSEPPE , GULLO FRANCESCA , LI BING , MILOVANOV YURII , RIQUET GUILLAUME

-

Construction and Building Materials

Permanent staff: PAVESE MATTEO , TULLIANI JEAN MARC CHRISTIAN

Researchers (RTDA): LAVAGNA LUCA

-

Materials for high temperatures and nanocomposites

Leader: BADINI CLAUDIO FRANCESCO

Permanent staff: ACTIS GRANDE MARCO , AVERSA ALBERTA , BASSINI EMILIO , BIAMINO SARA , COPPOLA BARTOLOMEO , DOGLIONE ROBERTO , FINO PAOLO , LOMBARDI MARIANGELA , MARCHESE GIULIO , MONTANARO LAURA , OSTROVSKAYA OXANA , PADOVANO ELISA , PALMERO PAOLA , PAVESE MATTEO , TULLIANI JEAN MARC CHRISTIAN , UGUES DANIELEPhD, Post-docs and Grant researchers:

DI SANNIO CHRISTIAN , DI STURCO SAMUELE , LERDA SERENA

DI SANNIO CHRISTIAN , DI STURCO SAMUELE , LERDA SERENA

-

Metallic Materials

Permanent staff: ACTIS GRANDE MARCO , AVERSA ALBERTA , BADINI CLAUDIO FRANCESCO , BASSINI EMILIO , BIAMINO SARA , DOGLIONE ROBERTO , FINO PAOLO , LOMBARDI MARIANGELA , MANFREDI DIEGO GIOVANNI , MARCHESE GIULIO , OSTROVSKAYA OXANA , PADOVANO ELISA , PAVESE MATTEO , UGUES DANIELE , VITALE BROVARONE CHIARA

Researchers (RTDA): GOBBER FEDERICO SIMONE

PhD, Post-docs and Grant researchers:

ARCIERI NICOLO' , CERONI MARTA , DI SANNIO CHRISTIAN , DI STURCO SAMUELE , FELICIONI STEFANO , FRACCHIA ELISA , LERDA SERENA , PENNACCHIO ANTONIO , TROVATO MIRKO , VANZETTI MATTEO

ARCIERI NICOLO' , CERONI MARTA , DI SANNIO CHRISTIAN , DI STURCO SAMUELE , FELICIONI STEFANO , FRACCHIA ELISA , LERDA SERENA , PENNACCHIO ANTONIO , TROVATO MIRKO , VANZETTI MATTEO