METENG - METallurgical ENGineering

Mission

The Institute of Metallurgical Engineering deals with researches on both ferrous alloys (including plain, low alloy, high-alloy and stainless steels, and cast irons) and non-ferrous alloys (including alloys based on aluminum, magnesium, titanium, and zinc), both innovative and traditional, used in the automotive, mechanical, chemical, food, energy, and building sectors. Compositional, microstructural, fractographic, mechanical and electrochemical tests are employed and interpreted on the basis of the principles of physical metallurgy and mechanical metallurgy. Corrosion and protection, wear and damage of metals and alloys are also studied experimentally and theoretically. Studies are performed on metals submitted to bulk heat treatments and to surface hardening treatments, as well as on coatings for corrosion protection or for other functional purposes. Industrial production methods, including casting, hot and cold forming, powder metallurgy, welding and additive manufacturing are also studied. Further lines of study include failure analysis and hydrogen compatibility of metals and alloys.

Main targets

- Microstructural and mechanical properties of steels and other metallic alloys

- Thermal and thermochemical treatments applied to ferrous materials

- Metallurgical effects of welding on steels and aluminum alloys

- Electrochemical behavior of metallic materials

- Compatibility of metallic materials with hydrogen

- Historical manufacturing processes of metallic materials

- Production of lightweight metal components

Main research topics

- Metallurgical analysis of steels, cast irons and aluminum alloys, based on chemical, metallographic, roengtenographic and fractographic analyses.

- Production processes and microstructural and mechanical properties of steels and aluminum alloys.

- Thermal and thermochemical treatments on ferrous materials and aluminum alloys. Traditional and innovative steels. Surface thermochemical treatments.

- Effects of welding of steels (non-alloyed and stainless) and aluminum alloys.

- Fracture mechanics and failure analysis and prevention.

- Electrochemical behavior of metallic materials. Corrosion and protection of plain and alloy steels and of Mg, Al, Ti, Cu, Ni and Co based alloys.

- Compatibility of metallic materials with hydrogen and hydrogen embrittlement phenomena

- Historical manufacturing processes of metallic materials and their microstructural and mechanical effects

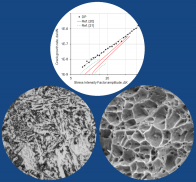

- Production of porous metal components, with good shock and/or vibration absorption properties

Main partnerships

- Centro Ricerche FIAT (Torino)

- Punch Torino S.p.A. (Torino)

- Siad Macchine Impianti S.p.A (Bergamo)

- Museo della Armi L. Marzoli (Brescia)

- J-Tech - Laboratorio interdipartimentale sulle giunzioni - Politecnico di Torino

- Endurance S.p.A. (Chivasso, TO)

- Dynacast Italia Torino S.p.A (Grosso, TO)

Projects and publications

-

Selected recent publications

2023

Selected recent publications

2023-

Corrosion Behaviour of Zr-Ag Alloys for Dental Implant Application

Article

Rosalbino, Francesco; Macciò, Daniele; Scavino, Giorgio

MATERIALS SCIENCES AND APPLICATIONS

Scientific Research Publishing

Vol.14 pp.14 (pp.501-514) ISSN:2153-117X DOI:10.4236/msa.2023.1411033 -

Synthesis and wear behaviour analysis of SiC- and rice husk ash-based aluminium metal matrix composites

Article

Mustafa, Sameen; Haider, Julfikar; Matteis, Paolo; Murtaza, Qasim

JOURNAL OF COMPOSITES SCIENCE

MDPI

Vol.7 pp.15 (pp.1-15) ISSN:2504-477X DOI:10.3390/jcs7090394

-

Co-Casting of Al and Al-Foams

Article

Ferraris, Sara; Santostefano, Antonio; DE MARCO, Frediano; Campagnoli, Elena; Matteis, Paolo; Barbato, Antonio; Molina, Roberto; Ubertalli, Graziano

ADVANCED ENGINEERING MATERIALS

Wiley

pp.13 ISSN:1527-2648 DOI:10.1002/adem.202200116

-

Electrochemical corrosion behavior of LDX 2101® duplex stainless steel in a fluoride‐containing environment

Article

Rosalbino, Francesco; Scavino, Giorgio; Ubertalli, Graziano

MATERIALS AND CORROSION

© 2020 WILEY‐VCH Verlag GmbH & Co. KGaA, Weinheim

Vol.71 pp.8 (pp.2021-2028) ISSN:1521-4176 DOI:10.1002/maco.202011826 -

Al-Based Metal Foams (AMF) as Permanent Cores in Casting: State-of-the-Art and Future Perspectives

Article

Ubertalli, Graziano; Ferraris, Sara

METALS

MDPI

Vol.10 pp.20 ISSN:2075-4701 DOI:10.3390/met10121592 -

Automatic Measurement of Pearlite Spacing by Spectral Analysis

Article

Matteis, Paolo

METALLOGRAPHY, MICROSTRUCTURE, AND ANALYSIS

Springer

pp.7 ISSN:2192-9262 DOI:10.1007/s13632-020-00630-9 -

Welding between aluminum alloy and steel sheets by using transition joints

Article

Matteis, P.; Gullino, A.; D’Aiuto, F.; Puro, C. M.; Scavino, G.

JOURNAL OF MATERIALS ENGINEERING AND PERFORMANCE

Springer

Vol.29 pp.14 (pp.4840-4853) ISSN:1059-9495 DOI:10.1007/s11665-020-04595-2

-

Influence of iodide ions on corrosion of dual‐phase steel in sulfuric acid solution

Article

Rosalbino, F.; Scavino, G.

MATERIALS AND CORROSION

WILEY‐VCH Verlag GmbH & Co. KGaA, Weinheim

Vol.70 pp.8 (pp.2033-2040) ISSN:1521-4176 DOI:10.1002/maco.201910884 -

Mechanical performance of historical wrought iron rods

Article

Matteis, P.; Scavino, G.

ARCHAEOMETRY

Wiley

Vol.61 pp.13 (pp.1053-1065) ISSN:0003-813X DOI:10.1111/arcm.12470 -

Review of Aluminum-To-Steel Welding Technologies for Car-Body Applications

Article

Gullino, Alessio; Matteis, Paolo; D’Aiuto, Fabio

METALS

MDPI

Vol.9 pp.28 ISSN:2075-4701 DOI:10.3390/met9030315

-

Corrosion Behaviour of Zr-Ag Alloys for Dental Implant Application

Reference laboratories

- Electrochemical Measurements Laboratory

- Mechanical testing Laboratory

- Optical Microscopy Laboratory

- Roentgenografy Laboratory

- Thermal treatments Laboratory 1